Condition Based Monitoring Services

Proactive Solutions for Peak Performance

Vibration Analysis

- Detect and prevent mechanical faults like imbalance, misalignment, and bearing issues.

- Identify early signs of wear and tear to avoid unexpected failures.

- Use state-of-the-art sensors for precise vibration monitoring.

Temperature Monitoring

- Monitor critical components for abnormal temperature changes.

- Ensure optimal operating conditions and prevent overheating.

- Real-time alerts for temperature-related anomalies.

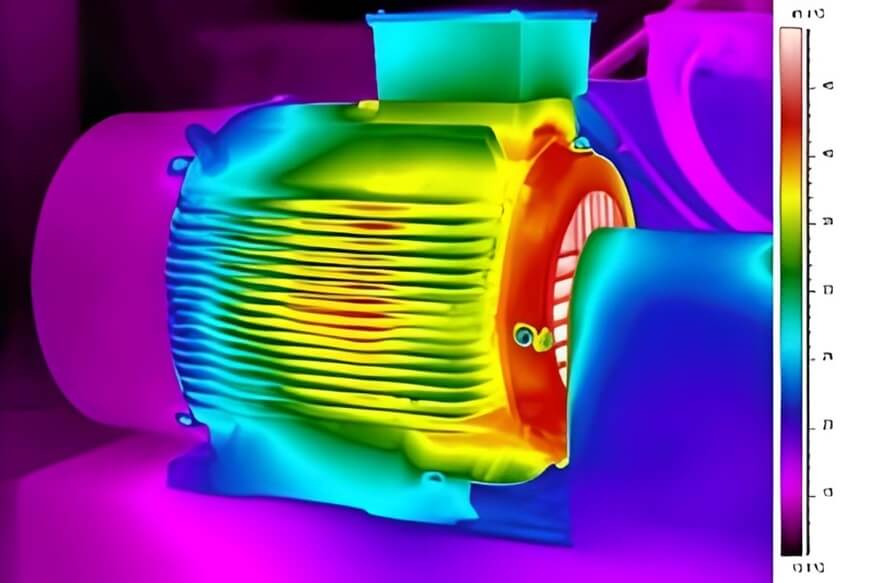

Thermography Analysis

- Identify hot spots and electrical faults using infrared imaging.

- Prevent energy loss and equipment failures.

- Enhance system reliability with non-invasive thermal inspections.

Oil Analysis

-

- Evaluate lubricant quality to detect contamination and wear particles.

- Extend equipment life by maintaining optimal lubrication.

- Regular oil sampling and laboratory testing for accurate insights.

Data Analysis

- Collect and analyze equipment performance data for actionable insights.

- Use advanced algorithms to predict maintenance needs.

- Optimize maintenance schedules for improved efficiency and cost savings.

At Westtixes Engineering, we specialize in Condition-Based Maintenance (CBM) to keep your machinery and equipment operating efficiently. By utilizing advanced diagnostic tools and techniques, we help you identify potential issues before they lead to costly downtime.

Why Choose Our CBM Services?

- Cutting-Edge Technology

- Reduced Downtime

- Cost-Effective Maintenance

- Customized Solutions

Innovate, Secure, Excel: Tech Canvas

Embark on a technological journey with Westtixes Engineering, where innovation, advancement, and leadership seamlessly come together to redefine the possibilities in the realm of technology.